TC-60 On-Site HOCl Generator

Hypochlorous Acid Generator, Toxic Free Solution

TC-60 Small–Medium Scale HOCl Generator

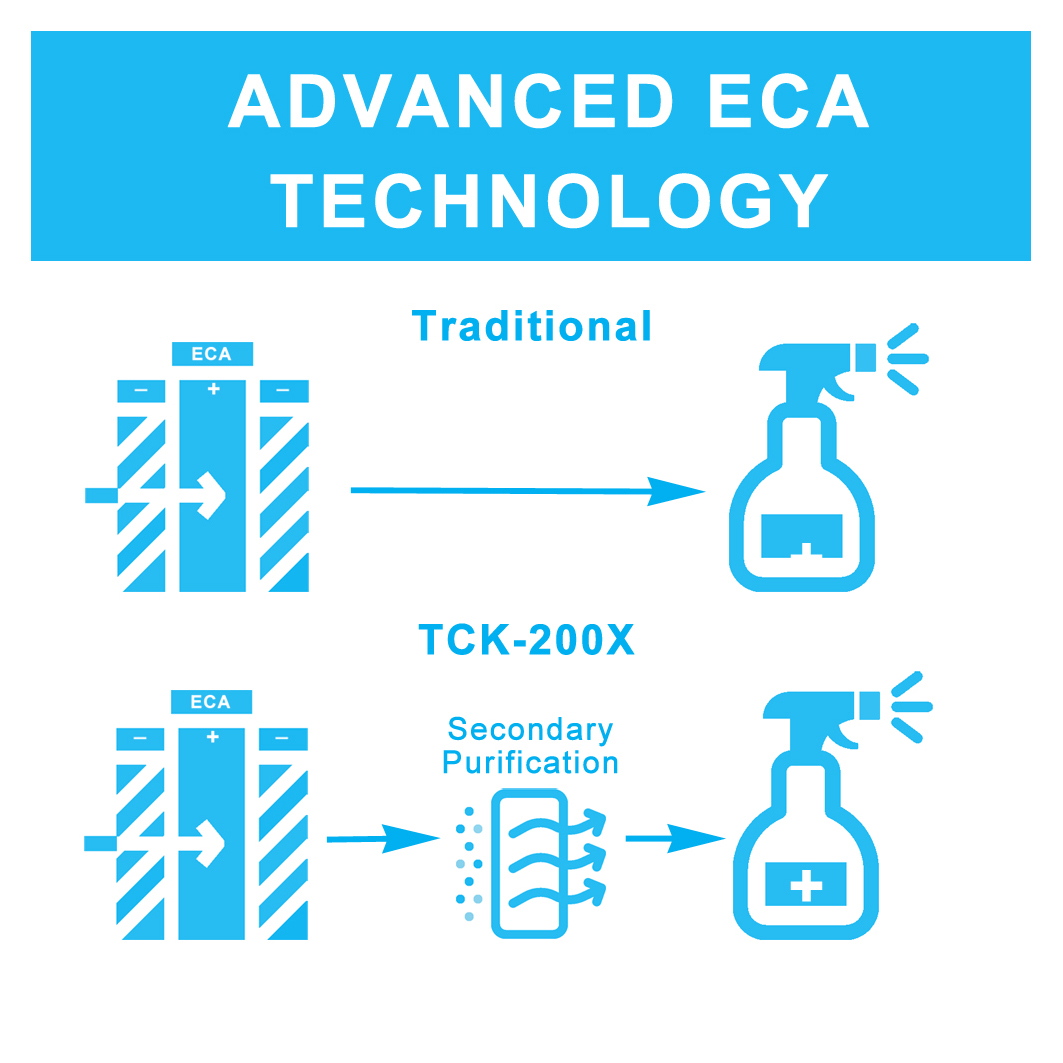

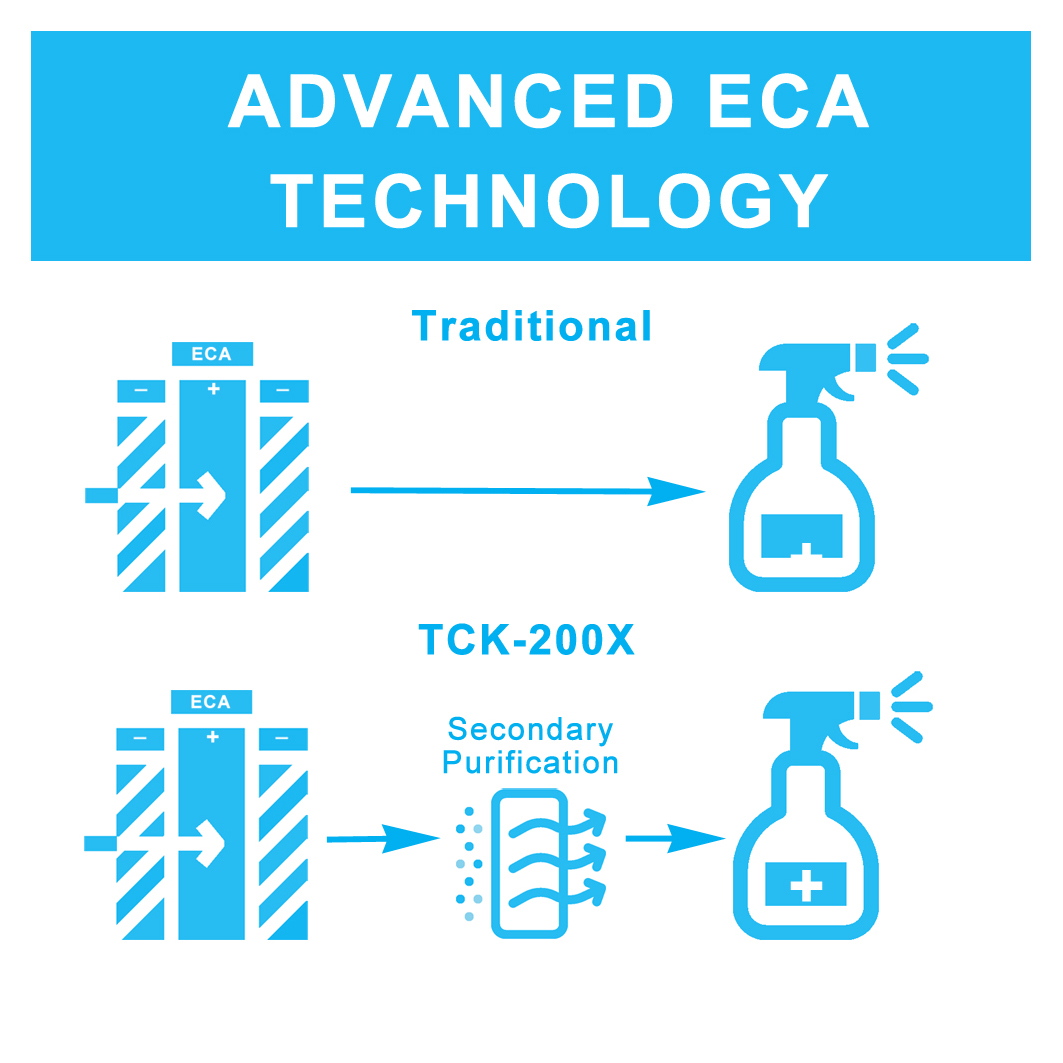

Engineered with cutting-edge electrolysis technology and protected by 23 domestic and international patents, this advanced disinfection system delivers a 99.9% antibacterial rate with zero residue. Unlike traditional methods, it employs a vacuum-type precision reactor and a secondary purification process to remove NaOH and residual NaCl by-products completely. The result is a safe, non-irritating hypochlorous acid solution—ideal for applications requiring high-level hygiene and environmental safety.

Replacing Your Traditional Cleaners and Disinffectants

Traditional ECA disinfectants often contained unsafe by-products like chlorite due to incomplete electrolysis.

Traditional ECA disinfectants often contained unsafe by-products like chlorite due to incomplete electrolysis.

The HKE TC-60 features an advanced dual-chamber electrolysis module with a secondary purification process that completely removes NaOH and impurities from the NaCl reaction byproducts, ensuring a professionally validated high-purity, low-residue system.

WHY USE TC-60

TC-60 is an environmentally-friendly disinfectant with versatile applications across various industries, effectively eliminating bacteria and minimizing disease transmission risks.

Comprehensive Disinfection and Deodorization Solution

Livestock Farming

Livestock Farming

Milking equipment and udders, feed troughs and drinking water systems, entry and exit passages, Birthing areas/stalls, hatcheries, deceased animal handling, surrounding deodorization

Aquaculture

Aquaculture

Water disinfection before replenishment, regular water quality control in culture ponds, water tower filtration, Feed barrels and feeding equipment, shrimp fry transport boxes, disinfection before fish eggs/shrimp fry enter ponds

Slaughter and Processing Facilities

Slaughter and Processing Facilities

Animal receiving areas (holding pens/stalls), slaughter area, entry and exit points, Cutting and processing areas including work tables, equipment, soaking pools, cold storage, and packaging areas

Food & Produce Processing

Food & Produce Processing

Outer packaging surfaces, carts, surface cleaning of produce/ food/ eggs Knives, conveyors, worktables, weighing stations, cold storage areas, and food preservation

Agricultural Tissue Culture

Agricultural Tissue Culture

Orchids and aquatic plants, media, tools, Mycena (white mushrooms), Trichoderma (black mold), Penicillium, water sources, cooling towers, fruit trees, bottle seedling rooms, soil

Odor Removal

Odor Removal

Ideal for use in factories, animal farms, agricultural composting sites, chemical plants, garbage processing areas, smoking rooms, and spaces requiring formaldehyde or odor removal.

Effortless Efficiency and Streamline Processes

One Click is All It Takes!

Streamline your processes with a single click, allowing you to allocate manpower to more critical tasks.

Fully Automatic by PLC Control

Fully Automatic by PLC Control

Our PLC system features automatic water level detection, replenishment, and shutdown, offering a high level of automation that ensures precision throughout every stage of operation.

Online Monitoring for Peace of Mind

Online Monitoring for Peace of Mind

Our system is equipped with a state-of-the-art online monitoring system. Any abnormal values are promptly notified to our background system and simultaneously, WhatsApp Messenger receives anomalous messages, enabling us to identify and address issues in advance, thus preventing factory shutdowns.

Mechanical Specification

Engineered with cutting-edge electrolysis technology and protected by 23 domestic and international patents, this advanced disinfection system delivers a 99.9% antibacterial rate with zero residue. Unlike traditional methods, it employs a vacuum-type precision reactor and a secondary purification process to remove NaOH and residual NaCl by-products completely. The result is a safe, non-irritating hypochlorous acid solution—ideal for applications requiring high-level hygiene and environmental safety.

Replacing Your Traditional Cleaners and Disinffectants

Traditional ECA disinfectants often contained unsafe by-products like chlorite due to incomplete electrolysis.

Traditional ECA disinfectants often contained unsafe by-products like chlorite due to incomplete electrolysis. The HKE TC-60 features an advanced dual-chamber electrolysis module with a secondary purification process that completely removes NaOH and impurities from the NaCl reaction byproducts, ensuring a professionally validated high-purity, low-residue system.

WHY USE TC-60

TC-60 is an environmentally-friendly disinfectant with versatile applications across various industries, effectively eliminating bacteria and minimizing disease transmission risks.

| Feature | TC-60 Advanced Electrolyzed Antimicrobial Solution | Conventional Electrolyzed Antimicrobial Solution |

|---|---|---|

| Electrolysis Material | Salt | Salt |

| Purification Process | Yes (dual-chamber electrolysis + secondary purification) | No |

| Main Ingredients | Pure Hypochlorous Acid (HOCl) | Hypochlorous Acid or Chlorine Dioxide |

| Chlorine Gas Residue | None | Gaseous byproduct from HOCl generation |

| Mixed Byproducts | None – impurities removed at source | Contains NaOH, NaOCl, unreacted NaCl |

| pH Level | 5.0 – 6.5 (near-neutral, safe) | Typically alkaline |

| Safety | High — non-irritating, non-allergenic, skin-safe, harmless to animals/plants/cells, no residue | Low — may cause irritation or allergies, harmful to aquatic life, may leave odor residues |

Comprehensive Disinfection and Deodorization Solution

Livestock Farming

Livestock Farming Milking equipment and udders, feed troughs and drinking water systems, entry and exit passages, Birthing areas/stalls, hatcheries, deceased animal handling, surrounding deodorization

Aquaculture

Aquaculture Water disinfection before replenishment, regular water quality control in culture ponds, water tower filtration, Feed barrels and feeding equipment, shrimp fry transport boxes, disinfection before fish eggs/shrimp fry enter ponds

Slaughter and Processing Facilities

Slaughter and Processing Facilities Animal receiving areas (holding pens/stalls), slaughter area, entry and exit points, Cutting and processing areas including work tables, equipment, soaking pools, cold storage, and packaging areas

Food & Produce Processing

Food & Produce Processing Outer packaging surfaces, carts, surface cleaning of produce/ food/ eggs Knives, conveyors, worktables, weighing stations, cold storage areas, and food preservation

Agricultural Tissue Culture

Agricultural Tissue Culture Orchids and aquatic plants, media, tools, Mycena (white mushrooms), Trichoderma (black mold), Penicillium, water sources, cooling towers, fruit trees, bottle seedling rooms, soil

Odor Removal

Odor Removal Ideal for use in factories, animal farms, agricultural composting sites, chemical plants, garbage processing areas, smoking rooms, and spaces requiring formaldehyde or odor removal.

Effortless Efficiency and Streamline Processes

One Click is All It Takes!

Streamline your processes with a single click, allowing you to allocate manpower to more critical tasks.

Fully Automatic by PLC Control

Fully Automatic by PLC ControlOur PLC system features automatic water level detection, replenishment, and shutdown, offering a high level of automation that ensures precision throughout every stage of operation.

Online Monitoring for Peace of Mind

Online Monitoring for Peace of MindOur system is equipped with a state-of-the-art online monitoring system. Any abnormal values are promptly notified to our background system and simultaneously, WhatsApp Messenger receives anomalous messages, enabling us to identify and address issues in advance, thus preventing factory shutdowns.

Mechanical Specification

| Size/ Weight | 80 (L) x 80 (D) x 172 (H) cm/ TBD |

| Maxi. Operating Hour | 15 hours/ day |

| Concentration | 200 ppm +/- 50 ppm |

| Capacity | 1 ton/ hour (200 ppm) |

| Water Demand | 1 ton/ hour |

| pH | 5 – 6.5 pH |

| Installation Environment | 220V 1-Phase/ 1280W/ 50 – 60Hz, WiFi, Water |

| Standard Deployment | Generator x 1; brine stirring and storage barrel not included |